A Field Service Software like field force tracker can make the it easy to manage your field service team. It easy to schedule and reschedule jobs with simple drag and drop dispatching.

What Is A Work Order?

A work order is a formal request for maintenance, repair, or operations work that needs to be done. Included in the work order is all of the information pertaining to a maintenance task and outlines the process for completing that task. Additionally, a work order can include details on who authorized the job, who it’s assigned to, deliverables, any special instructions, drawings, and anticipated end results.

Work orders can be generated through a service request form (work request form) that is submitted by a staff member, customer, tenant or automatically created through work order management software, such as a Field Service Management (FSM) System like Field Force Tracker. Using FSM software to manage work orders provides additional information to technicians, checklists, access to documents, manuals, images, and more. In addition to the documentation of the tasks that were performed, labor expenses, materials issued from inventory, spot buys, and other expenses incurred for the job can also be captured within the work order.

Why are Work Orders Important?

The purpose of a work order is to initiate a task, clarify what is to be done, specify completion dates, and give special instructions as needed. FSM work order management software also helps organizations manage and maintain data on assets as well as on resources, expenses, and labor. Organizations have the flexibility to manage and schedule current and upcoming work, analyze data to make improvements, manage expenses, control labor costs, and remain compliant.

Service Requests (Work Requests) vs Work Orders

A Service Request (also referred to as a Work Request) is a request for a maintenance task that is submitted by a non-maintenance staff member or customer. When a service request is approved by the maintenance manager, they will assign a technician and schedule the task and a work order is created.

A Work Order is an authorization for the maintenance team to perform the maintenance task.

What Can Field Force Tracker FSM Work Order Software Do For You?

Our FSM Work Order Management software provides organizations with many benefits and features for users to easily:

- Create, manage, and prioritize work orders from anywhere.

- Maintain work history, share documents, and generate reports.

- Track technician’s work order time from start to stop of a task.

- Manage resource availability and assignments.

- FSM is a centralized system accessible from a computer or mobile device.

- Streamline workflows.

- Improve communications.

- Track Inventory.

- Many more capabilities.

Work Order Process Defined

Using FSM software makes the work order management process more efficient and streamlined. Some of the main components of a work order include creation, completion and recording.

Work Order Process

- Task is Identified.

- Service request or maintenance request is created.

- Request is approved and turned into a work order.

- Work order is assigned and scheduled.

- Work order is sent to the appropriate technician.

- Work order documentation is updated and completed.

- Work order is closed out.

- Work order information can be analyzed to get a better insight into the processes followed or the steps taken to resolve any issues.

What Are The Different Types Of Work Orders?

Standard Work Order

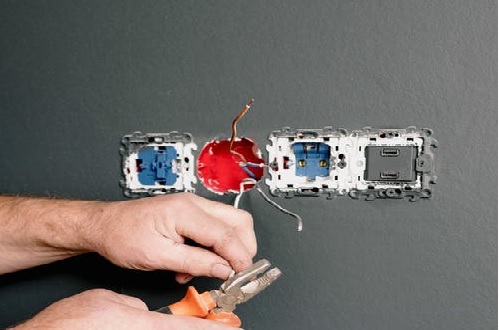

A standard work order is a non-critical maintenance task that does not pose an immediate risk to facilities, systems, equipment or components. Some examples are: removing old equipment, setting up new equipment, painting, or changing light bulbs.

Preventive Maintenance

A preventive maintenance work order is an essential tool for organizations looking to ensure the effectiveness of their equipment as well as to extend the life of their assets. This work order gives users the ability to schedule routine maintenance tasks on assets and equipment to minimize unexpected breakdowns. The preventive maintenance work order gives users the ability to control, plan, schedule, and identify the materials, parts, and labor to do the work within a specific timeframe. The advantages of preventive maintenance are to keep existing equipment in good working condition, prevent equipment downtime, increase the life expectancy of assets, decrease the number of major repairs, and control expenses.

Prepare for Inspections

When creating a work order, you can create a checklist and define a set of inspection points requiring a maintenance technician to audit or inspect an asset based on that predetermined set of parameters. If the technician should identify a problem during the inspection, then a new work order can be created to correct that problem.

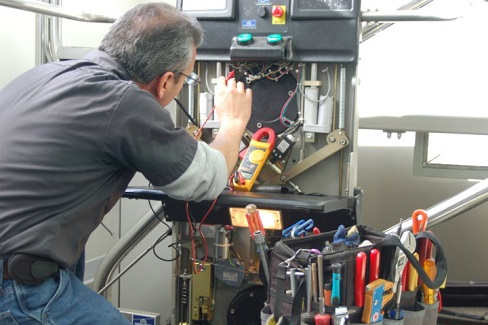

Reactive\Emergency

A reactive or emergency work order is generated when equipment breakdowns or a facility failure occurs and creates an unsafe environment, or a critical asset needs to be repaired immediately. An emergency work order is used to record and track and document any unscheduled work. Reactive work orders give maintenance technicians the ability to provide detailed information on what caused the breakdown, what actions were taken to fix it, and what can be done to prevent it in the future.

Corrective Maintenance

A corrective maintenance work order is generated as a result of a regular inspection, preventive maintenance, emergency, etc., which identifies the failure in a reasonable time for corrective maintenance to be planned and scheduled.

What Are The Benefits Of A Work Order?

Field Force Tracker FSM Work Order Management brings organizations the tools to effectively:

- Organize and manage work requests so nothing gets overlooked.

- Schedule work to be done at a convenient time.

- Control and manage labor overtime and expenses.

- Increase availability and performance of equipment.

- Better management and control of costs.

- Boost employee productivity.

- Preordering of supplies and materials.

- Improve customer service.

- Minimize paperwork.

- Reduce the maintenance backlog.

- Improve safety.

- Be compliant with company, state and federal regulations.

All of these benefits result in increased efficiency, productivity, safety, compliance and reduced costs.

Conclusion

Effective management of maintenance tasks is important to any organization. Work orders are a critical part of the management of these maintenance tasks. Field Force Tracker is a powerful FSM Work Order Management software that is designed to provide easy-to-use tools to streamline the processes to help you work more efficiently. With our FSM processes and procedures are defined, workflows are simplified, tasks are tracked, and information is well-documented.

Using FSM software to manage your work orders, maintenance teams will be more productive and work more efficiently.

If you are interested in learning more about how Field Force Tracker FSM Work Order software can help you automate your maintenance tasks, and would like to see a live demo, contact us today.